When printing anything structural you should choose at least 50% fill, which will take hours to complete. Before making such a commitment, you should first print out a very brief sample for measurement so to make sure the size is ok.

If you are using PLA, any holes for screws and kingpins should be made slightly larger than the original. A fitting that is too perfect can crack the material when being tightened.

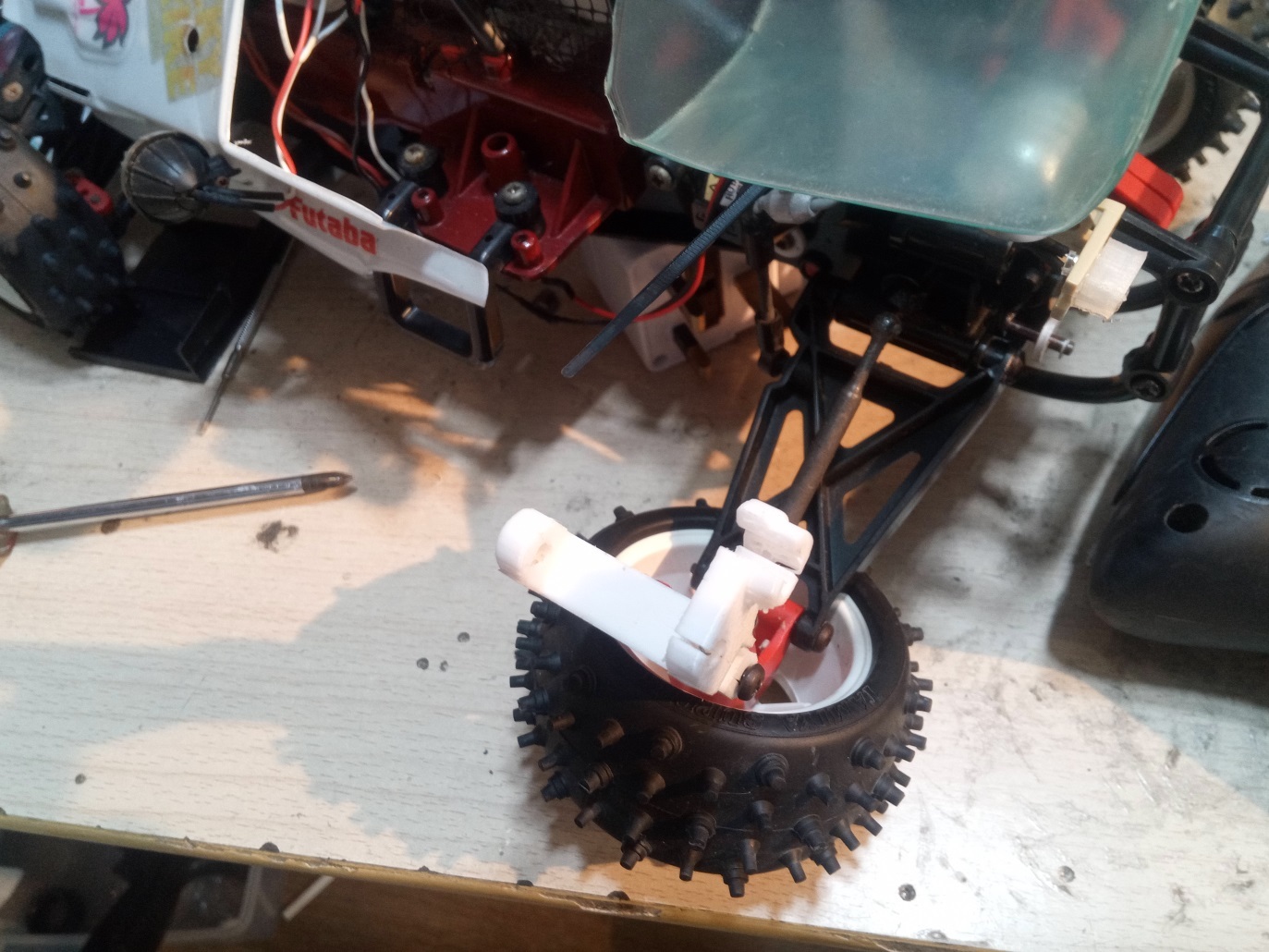

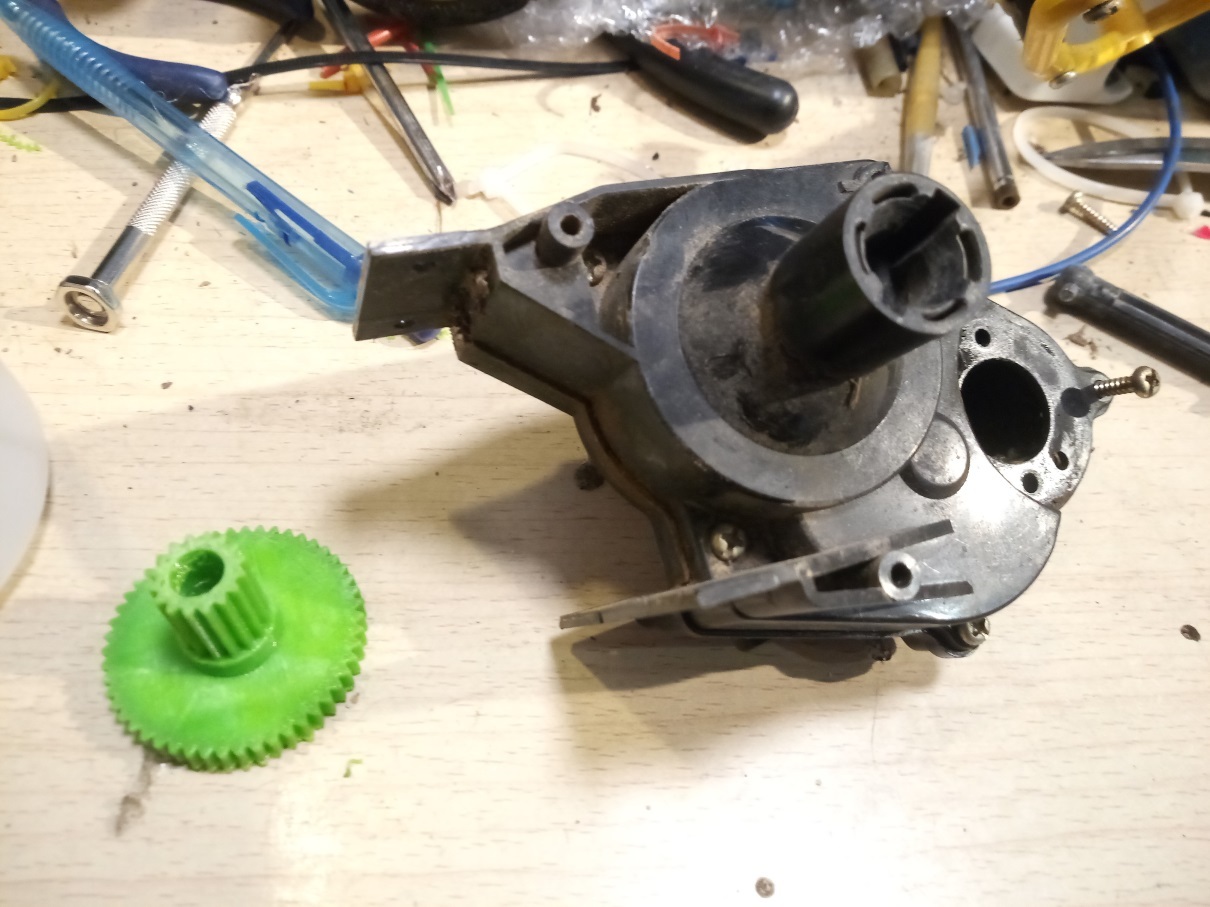

Still, when the design has stress constantly imposed on the parts, PLA may fail to hold up (time to consider ABS or Nylon instead). Simply put, 3d printed part using PLA has its limit in strength. As can be seen in this example configuration involving a rear suspension system, when pressure is constantly imposed on the part PLA just wouldn’t hold up even with 100% fill. This is both a design issue and a material issue. The original kit uses ABS and things start to crack when aged. A PLA replacement, however, fails real quick upon the first trial run. Unless you change the design, chance is that PLA will keep failing.

3D Printing Surface Coating Liquid can actually help in strengthening the 3d printed parts:

Recent Comments